Napier awarded a subsidy from ENOVA for the construction of world’s first zero-emission harvest vessel

ENOVA has awarded Napier NOK 123 million in investment subsidies for the development and construction of the company’s new hydrogen-powered harvest vessel, which will be the first in the world. «With this vessel, we can also offer our customers zero-emission ships and continue to make our mark on the industry in the future,» says Kjetil Tufteland, CEO of Napier.

Napier has been a pioneer in the harvest vessel sector since 2008 and, with its expertise and solid operational experience, has influenced an entire industry with its innovative solutions for delivering farmed fish. Over the past year, the company and a handful of partners have developed the concept for a hydrogen-powered vessel that enables improved fish welfare, zero biological emissions to the sea, and zero emissions to air—all in one vessel. On Wednesday, it was announced that ENOVA has awarded the new concept vessel a total of NOK 123 million in investment grants from the «Hydrogen in Vessels» support program.

Important Contribution

«This is a great day for us at Napier. The subsidy is an important and significant contribution to realizing a groundbreaking vessel that is currently otherwise not economically viable to order. We are therefore very pleased to have the opportunity to develop and further realize the project through this grant,» says Kjetil Tufteland, CEO of Napier.

He highlights three premises that will be crucial in the future transport of farmed fish: Increased fish welfare, high biosecurity, and zero greenhouse gas emissions.

«Fish welfare and biosecurity have already been established in our existing fleet and operational model, where we have been innovative for many years. With the new hydrogen-powered vessel, we can also offer our customers zero-emission vessels and continue to influence the industry into the future. The new vessel concept underlines the company’s values, which are based on a relentless pursuit of improvements in sustainable transport on the fish’s terms,» Tufteland states.

Interested Parties

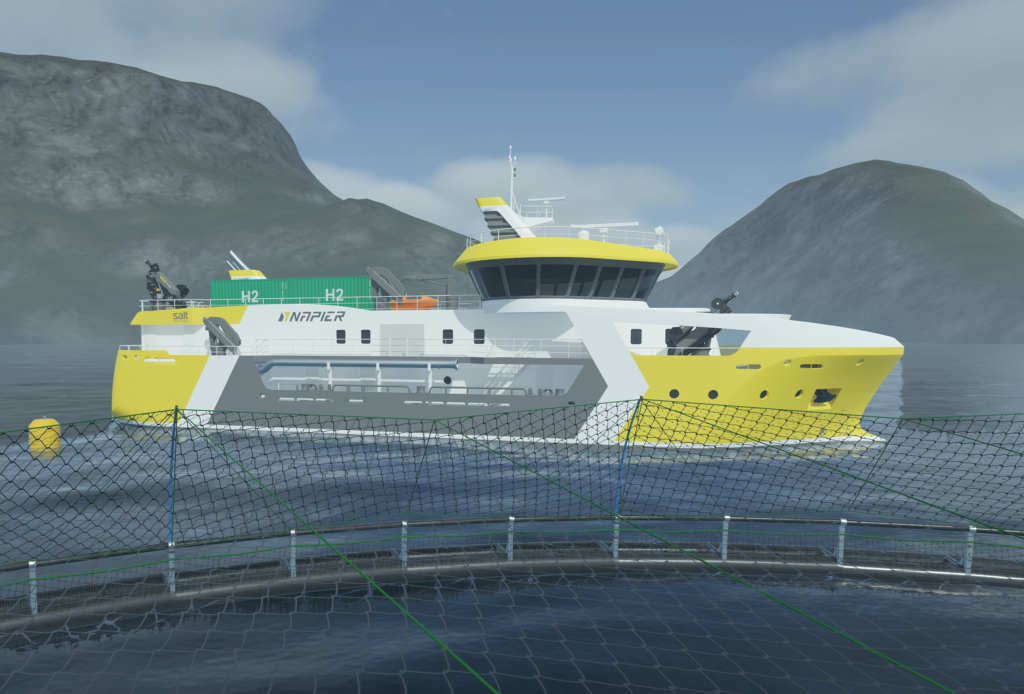

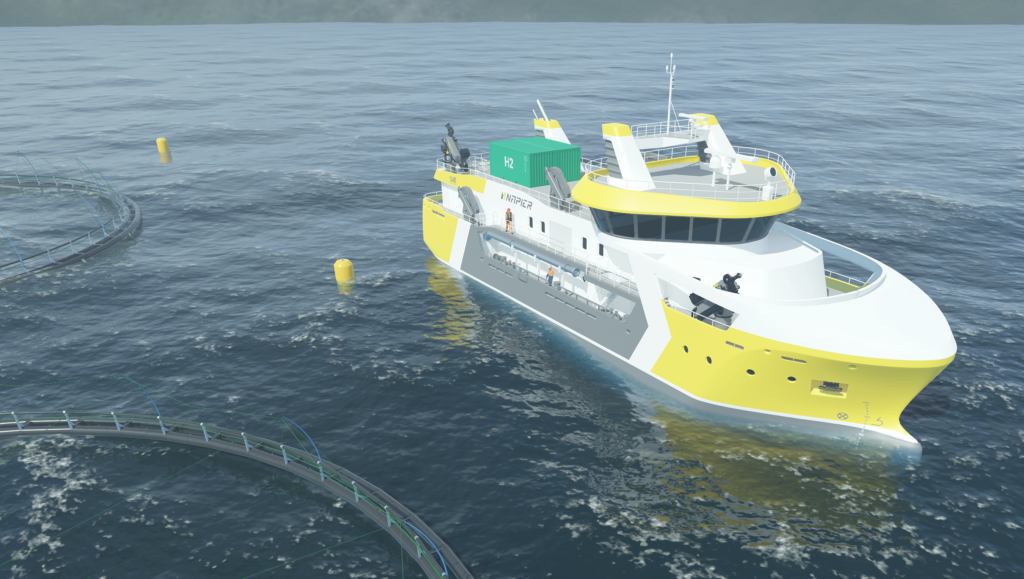

Napier’s new generation vessel will be approximately 50 meters long with a propulsion solution that uses compressed hydrogen as fuel in combination with battery technology. The concept is the result of close cooperation between Napier’s own experts, Salt Ship Design, Norwegian Hydrogen, LH2 Shipping, and the Green Shipping Program (DNV). The vessel will have a loading capacity of about 300 tons, making it suitable for the majority of Norwegian fish farming companies.

«We are in dialogue with several farmers who are interested in using the new concept and, of course, we want to get in touch with more players who want to sell their products with a reduced carbon footprint. This is a concept for players who want to lead the development of a more sustainable aquaculture industry where logistics naturally are a crucial part of the value chain. Personally, I hope to see the vessel delivered by 2027,» says Tufteland.

By using harvest vessels, the fish is slaughtered shortly after being loaded on board from the pen. The fish swims through a counter-current pool and into fully automatic stun and bleed machines before being transported further to the slaughterhouse in a cooled state. Each ship can thus transport fish more efficiently compared to the transport of live fish with wellboats, which requires the transport of large amounts of water. This means that smaller vessels can be used to transport the same amount of fish—already resulting in about a 50% reduction in greenhouse gas emissions compared to vessels for live transport, and this is before the hydrogen option now comes into play.

A shipping company preparing for growth

Jahn Helge Bjørnestad, Chief Commercial Officer at Napier, also highlights the transport of farmed fish as a perfect application for hydrogen powered vessels with zero emissions.

«Our ships have an operating profile with relatively fixed regional routes and frequent calls at a slaughterhouse. This gives us the opportunity to both refuel hydrogen and charge the battery pack during port stays for unloading and tank cleaning. Other vessel types often have less regularity in their operating profile, a much greater power need, and may not have the same bunkering opportunities. From an infrastructure perspective, the timing is also relevant as ENOVA’s new announcement for support for the development of hydrogen production for maritime transport is also expected to be clarified during the fall,» explains Bjørnestad.

Napier already has a fleet of four harvest vessels on long-term contracts along the entire Norwegian coast, and two new ships are under construction. These two will be the world’s largest harvest vessels and will transport fish to aquaculture giant MOWI’s brand new facility on Jøsnøya in Trøndelag.

For further information, please contact:

Kjetil Tufteland, CEO

Phone: +47 906 49 083

Email: Kjetil@napier.no

Jahn Helge Bjørnestad, CCO

Phone: +47 934 89 239

Email: jhb@napier.no

Napier in Brief

Through solid seamanship, high biological and process competence, and a willingness for continuous innovation and development, Napier takes care of the customer’s product all the way from pen to slaughterhouse. After starting as a wellboat operator in 1995, Napier became Norway’s first harvest vessel company in 2008. Today, the company is the leading player in this market with four vessels, all on long-term contracts for Norwegian fish farmers, and two new ships under construction. The company is headquartered in Bømlo and will have about 130 employees after the delivery of the two newbuilds.