Harvest vessels process the fish immediately, hence do not transport live fish. This means that more fish can be carried compared to live fish transport which requires large volumes of water. This results in smaller vessels requiring less fuel and subsequently reduced emissions per kilo fish transported. At the same time, more fish reaches the dinner table because mortality during loading, transport, and in holding pens is eliminated. This provides more kilos over which emissions can be distributed, creating a more sustainable product from the fish we transport.

Sustainability report

Our annual report can be downloaded by following the link (in Norwegian)

//

People

Napier AS will provide employees with a healthy and safe workplace, where proactive HSE efforts are made to prevent work-related injuries.

Napier AS will work to ensure a pleasant work environment for its employees, as well as the opportunity to participate in the development of their own working conditions.

The company will strive to ensure predictable working conditions for all its employees.

Animal welfare

Good fish welfare is a prerequisite for good fish health, low mortality, and high product quality. Napier shall be in the forefront of ensuring gentle handling of the fish, delivering products of top quality to our customers.

By ensuring good fish welfare, we contribute to better utilization of fish as a resource, while also ensuring that the fish are not exposed to unnecessary stress and pain.

Environment and biosecurity

Napier AS will ensure biosecure and environmentally friendly transport of fish, so that surrounding wildlife is not exposed to infections and/or substances that may cause harm.

Napier AS will also work to implement emission reductions in our operations and avoid any release of environmentally harmful substances.

Decent work and economic growth

We will operate in an economically sustainable manner in order to maintain a decent workplace for our employees, while also ensuring that financial considerations do not limit innovative solutions that can benefit the environment.

Food safety and regulatory compliance

Napier is committed to meeting all applicable requirements for food safety, including those from customers, certifications, and laws and regulations. The company will work proactively and continuously improve its systems to ensure that the products handled comply with, or exceed, requirements. The company will also promote a strong food safety culture within the organization.

Feedback

If you would like information about the services we offer and/or how the company manages actual and potential negative impacts, please click on “Feedback” to leave your message.

Certifications

As part of documenting the standards of our operations and the high requirements set by our customers, we are certified according to the GlobalGAP CoC, Aquaculture Stewardship Council CoC, and DeBIO standards.

GlobalGAP CoC

GG CoC no. Napier: 4059883895940. Our certification under the “GlobalGAP Chain of Custody” standard emphasizes our focus on high quality. Our customers can be confident that the way we handle our products meets the requirements set by the market.

ASC CoC

“Aquaculture Stewardship Council Chain of Custody”. The standard imposes strict requirements for environmental considerations, food safety, and traceability in connection with product handling.

Organic certification

In organic production, there are high standards for fish welfare and the environment, and we are able to assure our customers through robust control systems.

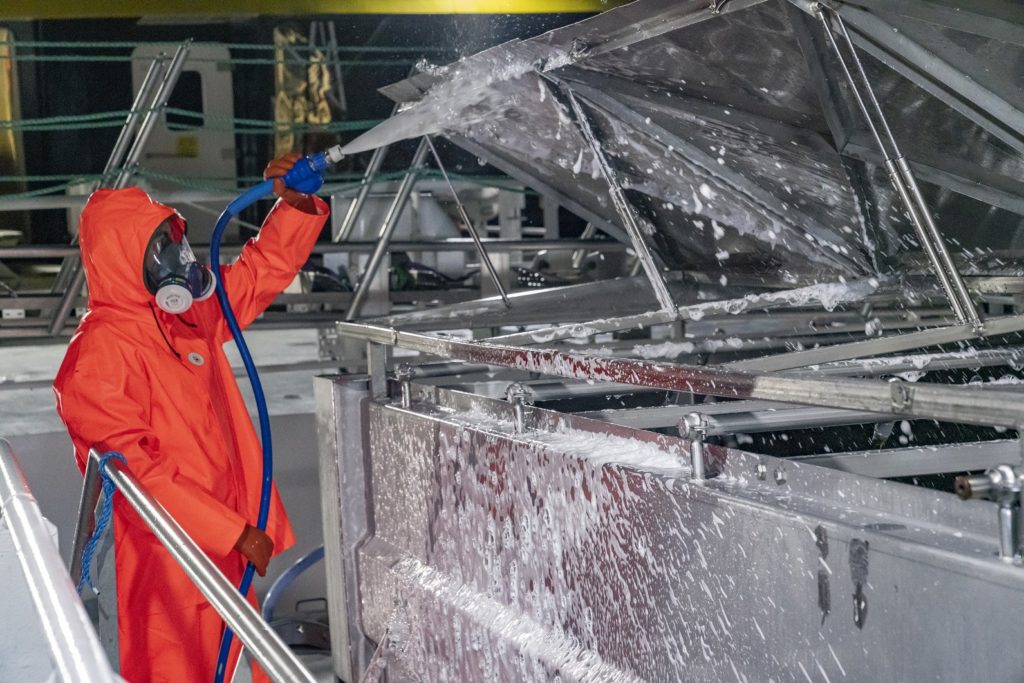

Cleaning

A well-developed cleaning and control regime is essential to ensure food safety. The vessels undergo an extensive washing and disinfection routine after each fish handling – the factory and associated equipment are manually washed and disinfected, while the piping system on board is cleaned using a “Clean In Place” (CIP) system. We have developed a CIP system that maintains the quality of the cleaning while keeping the cleaning time to a minimum. This system is based on over a decade of experience operating harvest vessels. Many effective solutions ensure proper drainage between cleaning steps, which further improves cleaning quality.

The cleaning is verified using various sampling methods, such as ATP tests, swab tests, and water samples, after each delivery of fish.